| Building A Digital Twin With Predix |

| Written by Kay Ewbank | |||

| Monday, 04 September 2017 | |||

Page 1 of 2 The concept of the digital twin is revolutionizing engineering. A digital twin is a virtual reality copy that is identical in every way to the 'real' version, apart from the fact it exists only in a digital form. A digital twin is accessible to whoever needs to use it. It is increasingly a mainstay of major construction and engineering projects. See how GE's Predix cloud platform makes it possible.

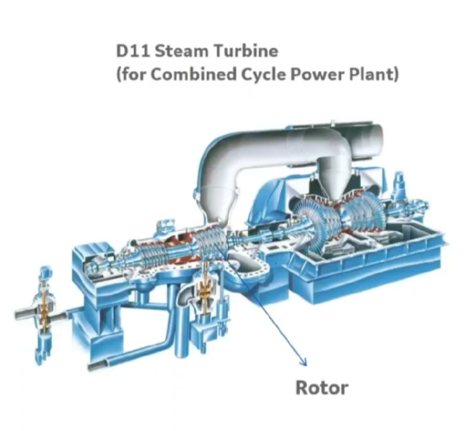

Companies are using digital twins to create a digital replica of its physical counterpart. For example, GE creates digital twins of products such as jet engines and wind turbines, along with digital twins of larger, more complex systems and assets. The digital twin holds all the information about its physical 'twin', from the history of how it was designed and built, through maintenance, and eventually the equipment's retirement or salvage. The information in the digital twin is available for anyone to use in order to understand how the product works, what maintenance it needs, and how it should be operated. The information for the digital twin is held in GE’s Industrial cloud-based platform, Predix.

To run a digital twin on the Predix system, you need the following services:

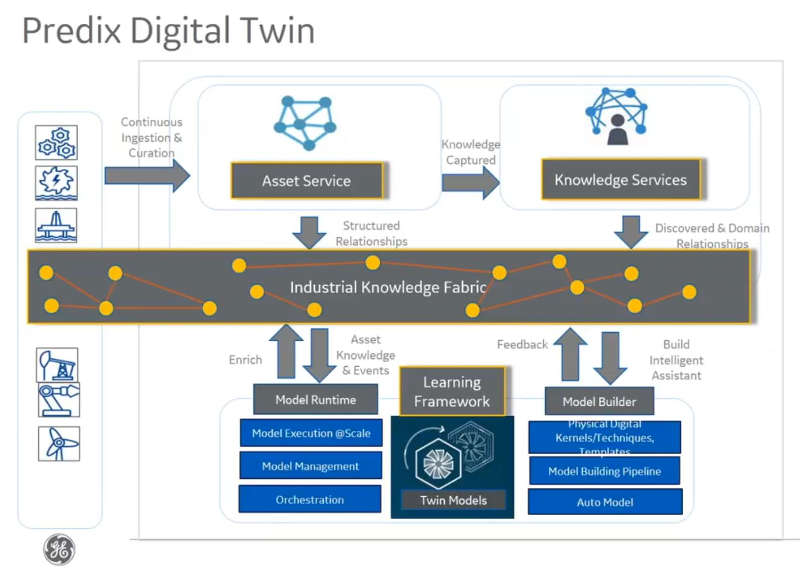

Building Digital TwinsThere are four fundamental elements to build a Digital Twin: Asset Service, Knowledge Service, Model Builder, and Model Run Time.

(click to expand) Asset ServicesAsset services consist of the hierarchy of assets, as well as the capturing and analysis of those assets. Asset services is also the part of the system that stores details of the relationship of the assets, the systems, subsystems, modules, components, parts and sensors that make up an asset. This element of the system also captures any configuration changes of an asset. Knowledge ServicesKnowledge Services is the element of the digital twin management system that curates the domain knowledge associated with an asset from the asset data and domain experts. In the industrial space data scientists have to work closely with domain experts to build models, because the assets can be so complex, and their design is very specific. It is often difficult to explain the design to end users, but decisions about a particular design can have major financial impacts, and getting a design 'right' is critical. Model BuilderThe Model Builder is the element of Predix used to model different facets of the digital twin. It uses machine learning, physics modelling, and other industrial analytics combined in a modular analytics authoring environment. Model RuntimeAnalytic models created in this module are published in the Digital Twin analytics catalog. The Model Runtime then executes, manages, and orchestrates these models. The other key element of Digital Twin is continuous learning. The twins can learn in four different learning modes; human learning, fleet learning, simulation learning and self-learning. This learning is applied in all the four stages discussed above. Providing InsightsA digital twin built using Predix can be used to provide information in three ways; it can provide early warnings of problems in the physical system; it can provide continuous prediction of the long term effect of current operation or usage; and it can be used for dynamic optimization. This uses multiple predictions and simulations to provide insights on possible improvements and optimizations. To see how this works, a jet engine is a good example. Companies such as GE have records going back 10-15 years of information from aircraft fleets about airplane flights. The data includes details such as the regions where engines are flying; the cycles and hours of operation; when the engines had maintenance and what was done. This was used to develop some limited fleet analytics, and to work out future business needs based on fleet level distributions. The data collection is now much more sophisticated and extensive. GE Aviation now monitors 35,000+ engines worldwide running on a variety of planes in many airlines.The airlines operate in regions of the world with extremes of climate - some engines fly in hot environments (up to 130 F), some are taking off in cold environments at - 50 F, some are operating in salty, sandy and dusty environments and some are operating in all the above. In addition to the environmental variation, the fleet of engines also experiences operational variation. Because of local conditions and airline requirements, some engines are in planes that climb quickly, others climb slowly. Some take off with a lot of thrust, others with less thrust. Some planes fly on short routes, others on long distance routes. Maintenance and inspection schedules also differ with local conditions: some countries in the Middle East are prone to dust so engines require more frequent inspection and maintenance. Countries like China and India have high amount of pollutants which are corrosive to metal parts, whereas planes operating only in North America encounter less pollution.

This data has enabled GE to create digital twins of the jet engines that provide deep insights about jet engine states at system level, part level, and at failure mode level. The information extracted can be used to create accurate inspection and maintenance plans, or customized fuel efficiencies. The reports help GE's customers generate maximum value from their assets. The Predix platform and ecosystem means GE customers can build, run and manage digital twins and deliver high business value at low cost. Data MattersOne thing that differentiates work like this in the industrial space from the consumer space is the amount of available data. It's easy in the consumer space to capture millions of data points based on end-users’ interactions. It is more difficult in the industrial space, because of the need to have enough of particular types of data points. For example, out of millions of flight data points, the number relating to aircraft engine failures are in single digits. This is fortunate for those flying in planes, but makes it more difficult to create an accurate digital twin. The cost of each transaction is also very high in the industrial space.

|

|||

| Last Updated ( Friday, 06 October 2017 ) |